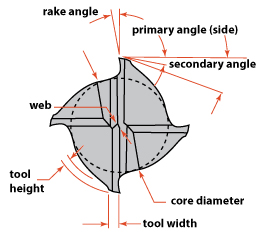

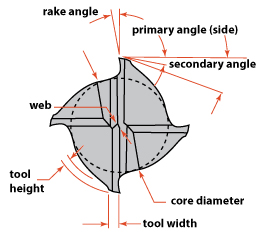

roughing end mill cutter diagram

Heavy cuts can be achieved because our roughing end mills have a much higher effective feed per tooth than a conventional end mill. The spiral flute end mill compared to a straight flute does a similar function.

Endmill Design Basics Mastercut Tool Corp

RT 100 Al Drills.

. HSS 4 flute wave edge end mill norm table. Two flute end mills are center cutting where multi-flute end mills can vary. Higher feed rate and depth of cut are utilized.

Search term 800 981 9663 800 981 9663. 2375 mm - 160 mm. It is measured from the start of the necked portion to the bottom of the cutting end of the tool.

Normally a 20 reduction in effective horsepower is used. A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds. Roughing end mills are also sometimes known as rippa or ripper cutters.

58 Roughing End Mill. Roughing End Mill Cutters Shop our selection of roughing cutters for use with any End Mill Notcher that requires a 125 shank. It is possibler to gash a rougher on a tool cutter grinder or even a pedestal grinder with a hand-formed saucer.

The overall reach of an end mill or length below shank LBS is a dimension that describes the necked length of reached tools. Objective of finish pass is to improve surface finish dimensional accuracy and tolerance. Typically the depth of cut will be less than or equal to the diameter of the cutting tool.

Silver 3Package Includes1 x Milling Cutter. Objective of rough pass is to remove bulk amount of excess material from workpiece in every pass. This will be the height of the chip produced.

Xtratec XT M5004 series. Often used in rough applications where deep cuts and low horsepower capabilities exist. Roughing End Mills for Aluminium Roughing End Mills for Al-alloy High speed milling over 6000ccmin ded.

Ball nose cutters or ball end mills lower row in image are similar to slot drills but the end of the cutters are hemispherical. 40 35 63 mm. Made of solid carbide these end mills are harder stronger and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material.

Roughing end mill Rough-cutters have notches or serrations on the cutting edge which like a mechanical shredder produces shorter easier-to-manage chips. Some end mills with fewer flutes are called roughing end. Optimum cutting data and tool life for maximum productivity Maximum process reliability thanks to high stability Perfectly adapted to the machining operation due to different indexable insert.

LHY HSS roughing end mill 4 flute. Normally Plunge Milling Specialty Cutters use flat-bottomed inserts but the round inserts were much less prone to chatter than the flat-bottom inserts. Roughers have chip-breaker cutting edges the peaks.

RT 100 XF High Performance Carbide Drill. Ball nose cutters or ball end mills lower row in image are similar to slot drills. A roughing end mill the type with a wavy corncob outer flute cuts into the part at a higher ratio to the rotation.

Roughing End Mills have scallops on the cutting edges which cause the chips to break into smaller segments. Regal Cutting Tools manufactures a variety of roughers for a wide range of materials and conditions. Roughers are one of the hardest tools to get right on a tool cutter grinder as the inside of the flute the top face has to be ground where-as a conventional end mill is sharpened by grinding the outside of the cutter.

CLICK to browse CORNER ROUNDING FINISHINGROUGHING END MILLS made by world class cutting tool manufacturer Guhring. Design that Virtually Eliminates Flute Packing and Obstruction. Many indexable tools cant cut in the center and many end mills are also not center-cutting.

These lower the shock load during the cutter rotation both enabling a heavier cutting load. Essential Tools for Machinists. A premium rupture resistant substrate is the foundation to.

Endmills are available in a wide variety of lengths diameters flutes and types and are chosen according to the material they are cutting and the surface finish required for the project. Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing. End Mills 5176 3 and 4 flute roughing end mills.

Side loading is dramatically reduced with lower helix angles making it easier to mill thin walls. Indexable insert milling cutter. The tooth design and flute construction minimizes deflection and maximizes chip ejection.

Fine-Pitch Roughing FPR FPR series milling cutters are fine-pitch HSSCo8 High-Speed Steel with 8 cobalt roughing end mills with Titanium Aluminum Nitride. Manufacturer and exporter of rough cutters. The neck relief allows space for chip evacuation and prevents the shank from rubbing in deep- pocket milling.

Roughing End Mill Cutter Related PostsEnd Mill CutterBall Mill CutterFace Mill CutterHollow Mill CutterSlab Mill CutterThread Mill CutterDovetail CutterFly Cutter. Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations. Our product line also includes thread taps and dies vernier calipers and digital products.

Very low feed rate and depth of cut are utilized. Roughing end mills are also sometimes known as rippa or ripper cutters. ROUGHING END MILLS Roughing cuts are generally for preparing the surface.

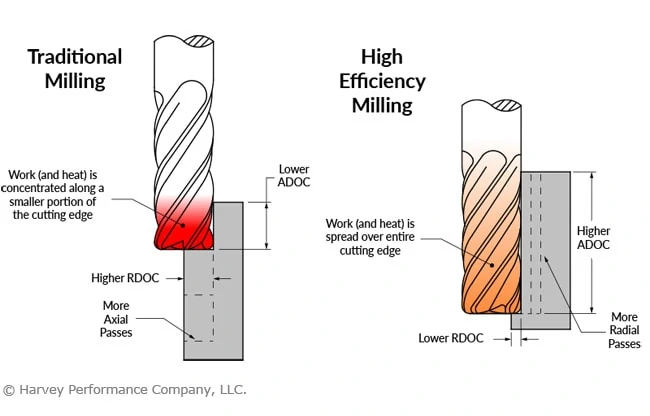

This results in lower cutting pressures at a given radial depth of cut. New Lower Prices on the Tools You Use Most. Roughing end mill ground from solid M42 8 c.

12 Roughing End Mill. Their extreme hardness means they are brittle so a highly rigid setup such as a CNC machine is necessary to prevent the end mill from. Cutting method Work material Revolution Feed rate End mill Short 3 flutes Roughing for Al-alloy.

Center cutting single end. HSS roughing end mill 4 flute schematic diagram. They are ideal for machining 3-dimensional contoured shapes in machining centres for example in moulds and dies.

Cobalt roughing end mills are designed. 78 Roughing End Mill. Multi-flute end mills create better surface finishes due to a lighter chipload - per flute.

One thing to be careful of when Plunge Milling is any cutting near the center of the tool. Product Data Sheets Users Guides Service Bulletins Safety Data Sheets Wiring Diagrams. Volumes of material can be removed at high cutting speed.

Not shown on the diagram. End Mills cut rotationally in a horizontal or lateral side to side direction whereas a drill bit only cuts straight down vertically into the material. Cobalt roughing end mills are designed to withstand heat and abrasion and can be run at higher production rates without sacrificing tool life.

Carbide Square End Mills. 3Straight Shank roughing Milling Cutter with 4 Flute. The SSDH series achieves superior chip flow and evacuation through the introduction of chip-release flute form technology and a unique inter-flute helical transition all within a patent pending design.

1 C-SRA C-MRA C-SRARB 616mm 25mm 655 Õ 5 10 30 50 70 1000 2000 3000.

End Mill An Overview Sciencedirect Topics

Mastercam 2021 Tutorial 93 Mill 3d Machining Mold Youtube In 2021 Mastercam Tutorial Molding

Factory Wholesale Corn Milling Cutter Head Bt40 Bmc63 76l Handle Whole Can Insert The Blade Numerical Control Milling Cutter Numerical Control Milling Cutter

Cutting Forces In End Milling Download Scientific Diagram

End Milling An Overview Sciencedirect Topics

Basic End Mills Technical Information Msc Industrial Supply Co

Pin On Woodworking Tips Tricks And Hacks

8 Ways You Re Killing Your End Mill In The Loupe

Two Flute End Mill Cutter Geometry Centre Cutting Type Download Scientific Diagram

Schematic Diagram Of The Side Milling Process Download Scientific Diagram